The #358 Johnstown Car

gets new wheels

Phase 1

The wheels on the #358 Johnstown Car are badly worn, and in need of major work. The plan for repairing the car is to remove the "trucks" (the wheel-sets under the car) and transport them to Connecticut for rebuilding, where they will get new wheels and brakes.

So, how do the wheels get removed from a trolley car, and how can they be moved to Connecticut?

If you think this sounds like a major job for a large crew using specialized equipment, well, here's how a crew of five (Bruce Thain, Richard Bause, Richard Edling, Fred Rasmussen, and Jon McGrew) handled the job in a couple of hours, with not-so-fancy equipment.

This project was directed by Bruce Thain, who will be rebuilding the trucks for us back in Connecticut.

Saturday,

April 5th, 2003, 1 PM:

It was a chilly day at the museum, following a night of freezing rain.

Bruce Thain brought his truck and materials from Connecticut

so that he could pick up the first of the two trucks

(wheel-sets) under the Johnstown Car and take it

to Connecticut for extensive rebuilding.

One truck had already been slid out from under the car

by Mike Hanna and others yesterday.

Richard Edling was on-hand to assist with the operation.

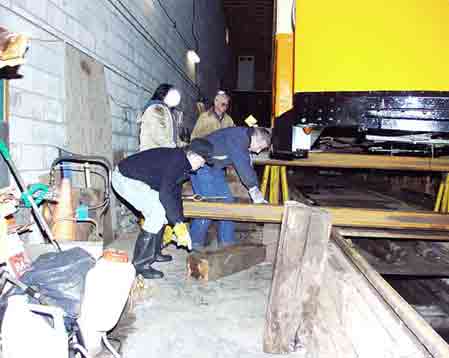

Rich Bause and Fred Rasmussen move blocks into position

for further support of the car.

Jacks and pilings are used on both sides of the car to support it

while the trucks are removed.

Bruce Thain, Fred Rasmussen, Richard Edling, and (foreground) Richard Bause

unload steel beams from Bruce's truck.

These will be used to support the car.

1:40 PM:

The first of the two beams has been slid under the car, to replace the previous, temporary supports.

One of the car jacks is visible right in the center of the picture; this is what lifts the car while the beams and pilings are slipped underneath.

The second beam is moved into place.

Arranging the supports on the other side.

2:00 PM:

The truck is rolled toward the front of the carbarn.

Rolling out the truck.

Bruce Thain determined that the best way to get the wheels

onto the flatbed of his vehicle is to hire a flatbed tow-truck

to load the wheels, and then transfer them to his truck.

We called for a flatbed.

2:00 pm: Right on schedule, the flatbed tow-truck arrived.

(...Most likely something of a new task for this tow-truck operator.)

The wheels are winched onto the flatbed truck.

2:15 PM:

With the wheels safely chained in place, the tow-truck operator heads out to the main parking lot,

where we have some maneuvering room.

Bruch Thain's truck is backed into position

behind the tow-truck, so that the wheel-set can be transferred to his truck.

The bed of the tow-truck is extended into position over the end of Thain's truck.

2:20 PM:

The operator of the tow-truck raises the bed of his truck up just a couple of inches,

so that the wheel-set can be rolled slightly downhill onto Bruce Thain's truck.

2:22 PM:

Touchdown!

By 2:30 PM, the Johnstown Car is looking slightly lonely

without the wheels that have supported it for many years.

But they'll be back!

By 3:00 PM,

the crew gets to relax for a minute and reflect on their work.

All packed up and ready for a trip to Connecticut.

Job well done!

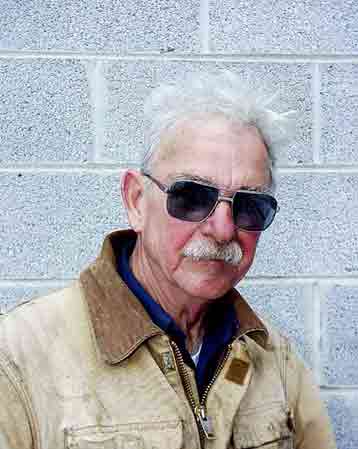

(L-R): Rich Bause, Fred Rasmussen, Bruce Thain, and Richard Edling. (Not in picture: Jon McGrew)

Rich Bause:

Hold that trolley!

Bruce Thain

Bruce Thain

Many thanks to

Bruce Thain

Photos and text by Jon McGrew

This page was last updated by Evan Jennings on May 5, 2003.